All

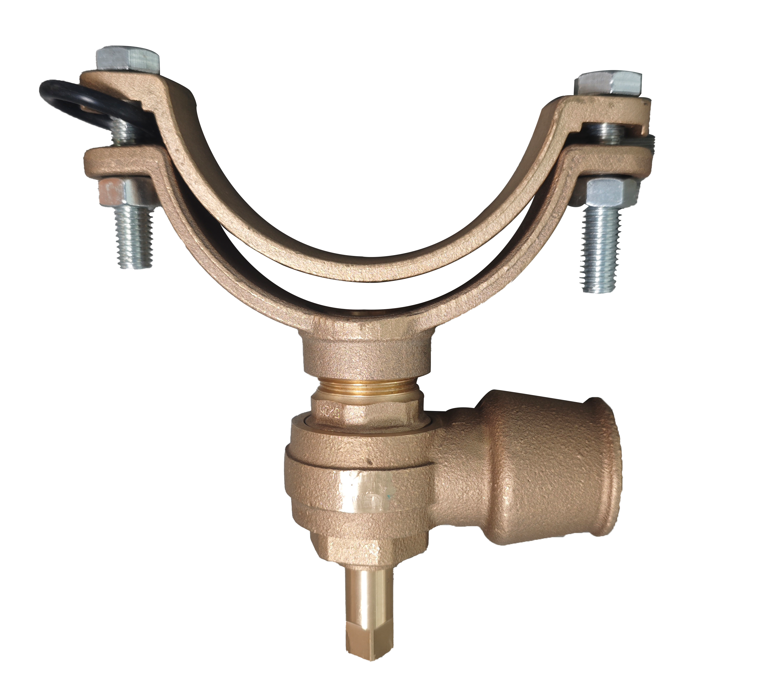

Brass sleeve valve

Brass Straight Ball Valve With Union

Brass Lock Valve With Nickel Plated For Saudi Arabic Market

L06 Female Thread Brass Magnetic Angle Type Lockble Valve

L05 Long Design Mechanical Handle Both Female Threaded Lockable Valve

L02 CW617N Brass Material Angle Type Anti Fraud Ball Valve

L04A Magnetic Angle Lockable Valve With Compression PE

BW-G07 KITZ Brass Gate Valve With Aluminum Or Iron Handle

Y-type Strainer

Y type Strainer is the filtration equipment which is to prevent impurities in the flow media from flowing into the back-end equipment. The strainer is usually being installed before the Water.

Features:

- Face to face: DIN3202-F1 / BS 2080

- Flanges: BS4504 / EN 1092-2 PN10/16

- Pressure Rate: PN10/16

- Hydraulic pressure test to EN12266 1.5 x PN

- Coating: Fusion bonded epoxy coating

Basket Filter

It is mainly composed of connection pipes, main pipes, filter baskets, flanges, flange covers and fasteners. When the liquid enters the filter basket through the main pipe, the solid impurity particles are blocked in the filter basket, and the clean fluid passes through the filter basket and is discharged from the filter outlet. When cleaning is required, unscrew the screw plug at the bottom of the main pipe, drain the fluid, remove the flange cover, and reinstall it after cleaning. Therefore, it is extremely convenient to use and maintain.

Foot Valve

Description

The foot valve is a kind of check valve. It is a valve used to prevent the medium in the pipeline from flowing back. The foot valve is opened when the medium flows downstream, and the foot valve is automatically closed when the medium flows backward. The foot valve is equipped with multiple water inlets on the bonnet, and is equipped with a screen to reduce the inflow of debris, which are not easy to be blocked.

Standards

▪ Size range: DN50 - DN300

▪ Connection Ends: EN 1092-2, PN10/16

▪ Nominal Pressure: PN10/16

▪ Temperature Range: 0℃ - 80℃

▪ Coating: Fusion bonded epoxy powder coating with min 250 microns thickness inside and outside

Pressure Differential Valve