Drain Valve

Drain Valve

Saddle & Repair Clamp

The product is composed of stainless steel shell and rubber gasket with special structure. It is used to repair quickly the leak point of pipe under working pressure.

The product can be used widely in the instant repair of pipes in these fields: water supply and sewerage, gas transfer,oil transfer, chemical industry, metallurgic industry, mineral industry, water power, electric power, marine.

Single Sphere Flanged Rubber Joint

Universal Flange Adaptor

The flange adapter is used for the connection between an ordinary end pipe and a flange valve device. This device makes the disassembly, assembly and maintenance operations on the pipeline more convenient.

Flap Valve

Rubber Flap Check Valve

Description

Rubber Flap Check Valve is designed to prevent reverse flow automatically. During system flow conditions,the movement of the fluid forces the valve disc to the open position allowing 100% UN - restricted flow area through the valve,Under reverse flow conditions,the disc automatically returns to the closed position to prevent reverse flow. The valve is of the swing check type utilizing an angled seat and fully encapsulated, resilient disc.

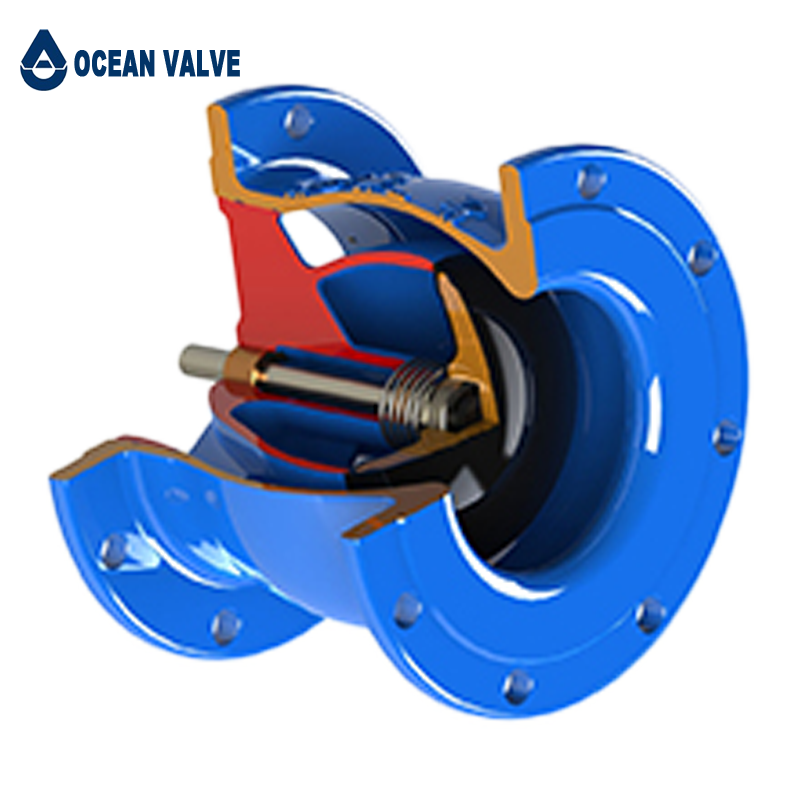

Flanged Ball Check Valve

Description

Ball check valves contain a ball that sits on the seat, which has only one through-hole. The ball has a slightly larger diameter than that of the through-hole (seat). When the pressure behind the seat exceeds that above the ball, liquid is allowed to flow through the valve. But once the pressure above the ball exceeds the pressure below the seat, the ball returns to rest in the seat, forming a seal that prevents backflow. The ball moves up and down inside the valve depending on the flow and seals against the machined seat when no flow or reverse flow occurs and seals against the seat to stop the reverse flow. Ball check valves are typically preferred for use in pumping stations as they are self-cleaning as the ball rotates during the operation and are vertically maintenance-free. IVALVE offers both flange and thread connections for the Ball Check Valves.

Threaded Ball Check Valve

Description

Ball check valves contain a ball that sits on the seat, which has only one through-hole. The ball has a slightly larger diameter than that of the through-hole (seat). When the pressure behind the seat exceeds that above the ball, liquid is allowed to flow through the valve. But once the pressure above the ball exceeds the pressure below the seat, the ball returns to rest in the seat, forming a seal that prevents backflow. The ball moves up and down inside the valve depending on the flow and seals against the machined seat when no flow or reverse flow occurs and seals against the seat to stop the reverse flow. Ball check valves are typically preferred for use in pumping stations as they are self-cleaning as the ball rotates during the operation and are vertically maintenance-free.Ocean offers both flange and thread connections for the Ball Check Valves.

Wafer Check Valve

Description

Dual plate wafer check valves, have two springs loaded half-moon shaped discs that rotate around their shaft. They are designed to automatically prevent back-flow in systems where it is desirable to permit flow in one direction and prevent flow in the opposite direction.

Swing Check Valve

Swing check valve is mounted with a disc that swings on a hinge or shaft. The disc swings off the seat to allow forward flow and when the flow is stopped, the disc swings back onto the seat to block reverse flow.

Ocean swing check valves are available in both resilient and metal sealing. It’s normally recommended for water and wastewater systems applications because of the simple construction, low pressure drop across the valve, and field service ability.

Tilting Disc Check Valve

Silent Check Valve

Description

Silent check valves, also known as non-slam check valves and spring-assisted check valves reduce or eliminate water hammer and its effects.

Water hammer refers to the high-pressure shock waves that occur when the flow of fluid abruptly stops (due to pump shut down or a valve disc quickly closing) in a piping system. When water hammer occurs, the resulting flow reversal places severe stress on the pipe, endangering its structural integrity, and opening it to potential rupture and damage.

To control water hammer and reverse flow, the use of silent check valves is recommended. When the source moving the fluid shuts down and the forward flow of the fluid decreases, the specially designed stainless steel spring action of the silent check valve controls the valve disc closure to occur prior to flow reversal. This spring assist insures that the valve does not slam shut, and the occurrence of water hammer is eliminated.

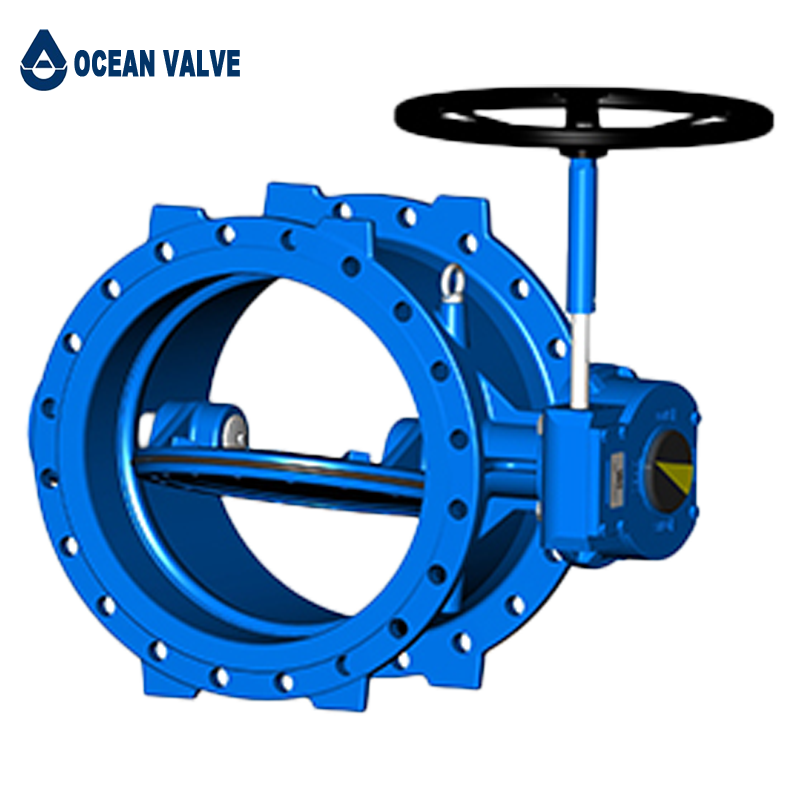

Double Eccentric Butterfly Valve

The center line of the disc rotation is horizontally and vertically offset from the body seat. This high-performance designeliminates“seat set” compression while the valve is in the open position.Compression on the seal is released after only a few degrees of opening which reduces friction and wear. This makes the valve ideal for modulation or in the open position for extended periods of time.

Dry Disc Hub

The advanced dry disc hub and shaft design is achieved through 10 O-Ring seals on both the upper and lower shafts. This prevents ground water and line media from entering the journal areas, resulting in ease of operation and minimal torque for many years.

Engineered Linings and Coatings

The Ductile Iron body comes electrostatic applied Fusion Bonded Epoxy coating.Testing is performed to ensure the valve meets the most stringent coating thickness and porosity requirements.